Insulating Glass Unit (IGU)

Insulating glass units (IGUs) are now widely used in commercial office buildings, shopping malls, high-rise residential buildings, and other structures as an energy-efficient glazing solution. They offer excellent thermal insulation, soundproofing, and an aesthetically pleasing, practical design.

An IGU consists of two (or more) glass panes bonded together with a spacer bar. The sealing methods primarily include gasket sealing (胶条法) and adhesive sealing (胶接法), with the latter being the most commonly used today—specifically the dual-seal adhesive structure.

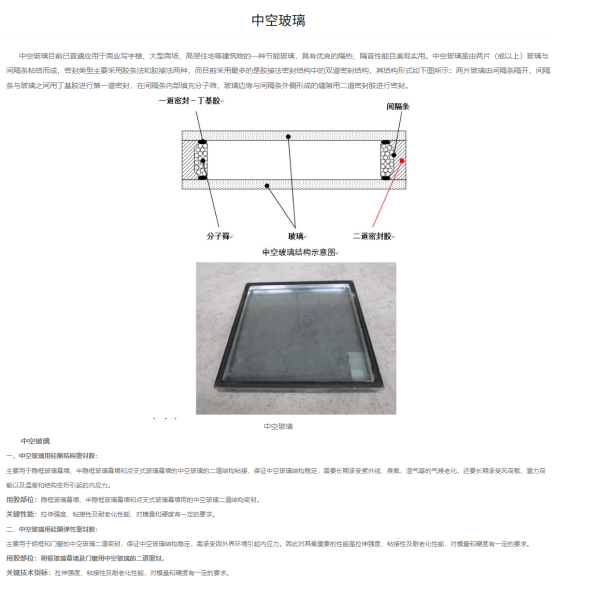

Structural Configuration (as illustrated below):

- Two glass panes are separated by a spacer bar.

- Primary seal: Butyl sealant is applied between the spacer bar and the glass panes.

- Desiccant filling: Molecular sieve (drying agent) is placed inside the spacer bar to absorb moisture.

- Secondary seal: A polysulfide or silicone-based sealant is applied to the outer edges of the glass and spacer bar to complete the airtight and watertight barrier.

Insulating Glass Units (IGUs)

- Structural Silicone Sealants for IGUs:

Primarily used for secondary structural bonding in:

- Stick curtain walls

- Semi-stick curtain walls

- Point-supported curtain walls

These sealants must:

- Ensure long-term structural stability of IGUs

- Withstand climate aging factors (UV, ozone, moisture)

- Endure sustained wind loads, gravity loads

- Accommodate stress from thermal expansion and structural deformation

Application areas: Secondary structural sealing for IGUs in the above curtain wall systems

1.Structural Silicone Sealant for Curtain Walls

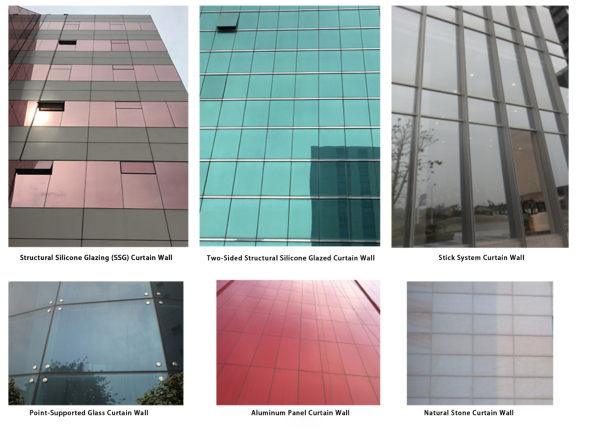

In modern architecture, traditional brick walls and masonry blocks are increasingly being replaced by curtain wall systems, including glass, stone, aluminum, ceramic, terracotta, metal, fiber cement, and other panel-based facades. These systems offer advantages such as aesthetics, energy efficiency, and easy maintenance. Silicone structural sealants are essential for bonding and assembly, while silicone weatherproof sealants are used for joint sealing.

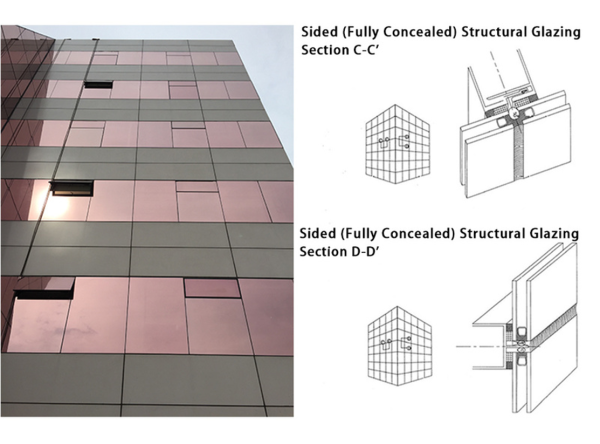

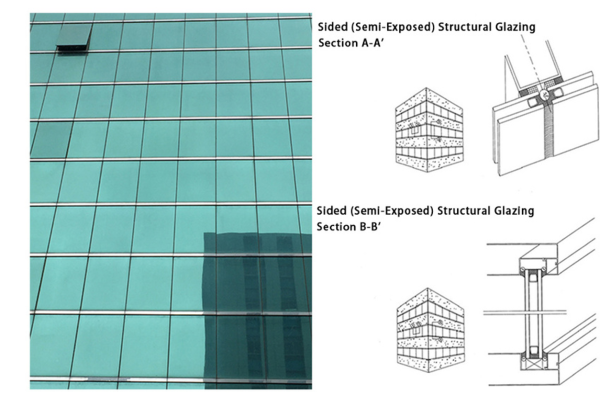

1. Silicone Structural Sealants for Curtain Walls

Silicone structural sealants are critical materials in Structural Sealant Glazing (SSG) systems, bonding glass directly to aluminum frames, which are then mechanically fastened to the curtain wall framework. Since the glass relies entirely on the adhesive strength of the sealant—while enduring long-term weathering and mechanical loads—its performance and durability are vital for the safety and longevity of the building facade.

Applications:

- Fully concealed frame curtain walls (4-sided structural bonding)

- Semi-concealed frame curtain walls (2-sided structural bonding)

- All-glass curtain walls (load-transferring joints, 2-sided structural bonding)

Key Technical Requirements:

Tensile strength, aging resistance, and a degree of elasticity.

(Word-for-word accuracy maintained while ensuring natural English flow.)

2.Weatherproof silicone sealant for curtain wall

Silicone weatherproof sealant is used for joint sealing in curtain wall systems (glass, metal, stone, etc.), ensuring air/water tightness. It must accommodate movement caused by thermal expansion/contraction of panels and structural displacement, requiring excellent elasticity and long-term crack resistance under cyclic joint movement.

Applications:

Joint sealing for glass/metal/stone/terracotta panel curtain walls

Key Technical Requirements:

Movement capability (elasticity, ±25% to ±50%)

Weather resistance (UV, temperature, moisture)

No strength requirement (high or low modulus acceptable)

Complies with:

ASTM C920 (Standard Specification for Elastomeric Joint Sealants)

ISO 11600 (Building construction – Sealants – Classification/Requirements)

Doors and Windows

The sealants used in the doors and windows industry are primarily applied to seal the joints between glass and window frames, as well as between window frames and concrete structures. Sealants play a crucial role in the performance of doors and windows, particularly in terms of watertightness, airtightness, thermal insulation, and soundproofing—factors that should never be underestimated.

Application Areas:

Sealing of joints between glass and aluminum frames, as well as between aluminum frames and concrete structures.

Key Performance Properties:

- Adhesion

- Movement capability

- Durability